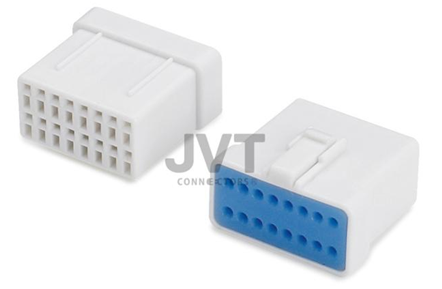

As a world-renowned connector manufacturer, JVT launched the JVT2070 series waterproof connector system with a 2.0mm pitch as the core design benchmark, and has been developed and produced to a maximum of 16 channels of 2 * 08 on the original basis. With its compact structure and reliable waterproof performance, it occupies an important position in harsh environment applications in many industries. This report will analyze the core parameters, application scenarios and core advantages of the product to provide reference for relevant industry selection.

Overview of the core technical parameters of the product

The performance advantages of the JVT2070 series waterproof connector system are based on accurate technical parameters, and its core indicators clarify the applicable boundaries and reliability of the product. The specific parameters are as follows:

parameter category | specific indicators | explain | |

Electrical performance | Rated current 3A AC/DC; Rated voltage 100V AC/DC; Insulation resistance 800MΩ | Suitable for medium and low power circuits, excellent insulation performance, reducing the risk of leakage | |

Waterproof grade. | IPX7 (IEC 60529 compliant; JIS C 0920 level 7 compliant) | It can be soaked in a water depth of 1 meter for 30 minutes without water entering, meeting the needs of moisture and short-term water immersion | |

Environmental adaptability | Working temperature -40 ℃~ + 105 ℃ | Extreme high and low temperature resistance, suitable for complex environments such as outdoor, industrial and automotive | |

structural parameters | 2.0Mm pitch, maximum 16 circuits; crimp connection method | Compact layout saves installation space, and the crimping process improves connection stability | |

Compliance | RoHS compliance, UL certified | Meet environmental and safety standards and adapt to global mainstream market demand |

Second, multi-domain product application scenario analysis

Based on the core characteristics of "waterproof and reliable + compact structure + environmental tolerance", the JVT2070 series connectors accurately match the pain points of multiple industries, forming a diverse application matrix. The specific scenarios are as follows:

1. Automotive electronics: reliable connectivity in the vehicle environment

The waterproof and shock resistance requirements of the connector are strict in the humid areas outside the cabin and inside the cabin. The JVT2070 series is an ideal choice due to its IPX7 waterproof rating and stable locking structure. Its typical applications include: connection of outdoor units of vehicle air conditioning, signal transmission of reversing video cameras, line interface of vehicle sensors (such as humidity sensors, temperature sensors), etc. In these scenarios, the connector needs to withstand continuous vibration and rain and snow during vehicle driving. The double spring contact structure and shell locking design of this series can effectively avoid poor contact and ensure the stable operation of driving safety-related systems. At the same time, the temperature range of -40 ° C to + 105 ° C can adapt to the extreme climate of cold in the north and high temperature in summer without additional protective measures.

2. Household appliance industry: safe adaptation to humid environments

Household appliances such as washing machines, dishwashers, humidifiers, etc. are in a humid or water splashing environment for a long time, and the waterproof performance of the connector is directly related to product safety. The solid rubber wire side sealing design of the JVT2070 series maintains a compact size while achieving IPX7 waterproof. It can be embedded in a narrow space such as the connection line between the water inlet valve of the washing machine and the control board, and the interface of the drive module of the dishwasher spray arm. Its low insertion force feature also facilitates the efficient assembly of the production process of home appliances. In addition, RoHS compliance ensures that the product meets the environmental protection requirements of the home appliance industry and adapts to the export needs of the global market.

3. Industrial and commercial equipment: stable support for complex operating conditions

In scenarios such as industrial control, vending machines, outdoor communication equipment, etc., connectors need to deal with multiple challenges such as dust, water vapor, and temperature fluctuations. The plug and socket of the JVT2070 series have a built-in locking structure, and with the integrated sealing ring of the head, it can effectively block dust intrusion and achieve waterproof sealing. It is suitable for the connection of the drinking water supply module of the vending machine, and the external line interface of the outdoor air conditioner. Its 3A rated current can meet the power supply needs of small motors, control modules and other equipment, while the double spring contact structure (main spring + auxiliary spring) can provide a stable contact force to avoid line interruption caused by vibration in industrial environments.

4. New energy and power equipment: safe connection of low-voltage systems

In low-voltage power systems such as small solar street lamps and household energy storage equipment, the JVT2070 series can be used for the connection between photovoltaic modules and controllers, and the auxiliary line interface of energy storage batteries. Its 100V rated voltage and 3A current are suitable for low-voltage scene requirements, and the IPX7 waterproof grade can cope with outdoor rain and ensure the continuity of energy transmission. At the same time, the high temperature resistance makes it able to work normally in the high temperature environment of the surface of photovoltaic panels in summer, improving the overall reliability of the equipment.

5. Second-round new energy field: waterproof safety barrier for outdoor travel

As a mainstream brand of two-wheel new energy travel equipment, Ninebot's products often face the test of outdoor rain, road water accumulation and muddy environment. The waterproof and anti-vibration performance of the connector is very important. The JVT2070 series perfectly adapts to the needs of this field with its IPX7 waterproof grade and compact structure. Typical applications include: signal connection between smart dashboard and battery management system, line interface of lighting system (turn signal, brake light), power supply and signal transmission of on-board sensors (inclination sensor, speed sensor). During riding, the equipment will withstand bumps and vibrations and rain splashes. The double spring contact structure and shell lock design of this series can effectively prevent contact loosening and ensure accurate transmission of driving data and stable response of the safety system. In addition, the wide temperature range of -40 ° C to + 105 ° C can be adapted to low temperature start-up in winter and sun exposure in summer, enabling stable operation without additional protection and enhancing user travel safety.

6. Power tool industry: Durable connection solutions for severe conditions

Power tools (such as electric drills, angle grinders, high-pressure cleaners, etc.) are mostly used in construction sites, outdoor decoration, household cleaning and other scenarios. They are often exposed to dust, sewage and concrete debris, and the protection and durability of the connector are extremely high. The dual protective structure of JVT2070 series "head sealing ring + wire side rubber seal" can effectively block the intrusion of dust and sewage. It is suitable for scenarios such as the connection between the body of the high-pressure cleaner and the power cord, and the motor control circuit interface of the electric drill. Its 3A rated current can meet the power supply needs of medium and low power power power tools. The crimping connection method improves the anti-pull ability of the line and avoids the connection failure caused by cable dragging during tool use. At the same time, the impact resistance of this series can cope with the mechanical impact caused by the accidental drop of the tool, prolong the service life of the equipment, and reduce the maintenance cost, especially suitable for professional working conditions with high frequency and high intensity.

7. Bathroom industry: Exclusive protection solutions for humid and corrosive environments

The bathroom space has been in a high-humidity, multi-water and temperature fluctuation environment for a long time, and there is a risk of detergent corrosion, which places strict requirements on the waterproof, anti-corrosion and insulation performance of the connector. The JVT2070 series has become an ideal connection choice for bathroom smart devices due to its IPX7 waterproof grade and chemical-resistant shell material. Typical applications include: the connection between the flush control module of the smart toilet and the main control board, the temperature sensor circuit interface of the constant temperature shower, the lighting and defogging function power supply circuit of the bathroom mirror cabinet, and the water level detection and heating system interface of the smart bathtub. In these scenarios, the connector needs to continuously resist the large amount of water vapor generated by bathing, water splashing during cleaning, and chemical erosion of toiletries. The double sealing structure of this series can effectively isolate moisture and corrosive gases to avoid short-circuit failures. Its temperature range of -40 ° C to + 105 ° C can be adapted to the alternating hot and cold environment of the bathroom, ensuring the stable operation of smart bathroom equipment. In addition, the compact structure design can be embedded in a small space inside the bathroom equipment, which does not affect the product design and enhances the user experience.

III. Analysis of the product's core competitive advantage

Compared with similar waterproof connector products, the JVT2070 series has formed four core advantages through structural innovation and process optimization, as follows:

1. Balanced advantages of high-efficiency waterproofing and compact design

The series adopts a double sealing structure of "solid rubber wire side seal + head integrated sealing ring", which avoids the problem of excessive size of traditional waterproof connectors while achieving high waterproof grade of IPX7. The 2.0mm pitch design and streamlined shell structure make it easy to embed into narrow installation spaces such as household appliances and on-board electronics, solving the industry pain point of "waterproof performance and installation compatibility are difficult to balance". This structural design also reduces the wear of sealing parts and extends the service life of connectors.

2. Double guarantee of stable contact and low operating cost

The contact piece adopts a double-spring leaf structure of "main spring + auxiliary spring", which can provide continuous and stable contact force, effectively resist external disturbances such as vibration and impact, and reduce the risk of poor contact. At the same time, the spring-type terminal locking structure integrated with the shell realizes the combination of "low insertion force + firm locking" - the operator can complete the insertion and unplugging without the help of professional tools, reducing the difficulty of assembly; the locking structure can prevent accidental falling off and reduce later maintenance costs. This design is especially suitable for mass-produced home appliances and automobile manufacturing scenarios, which can improve production efficiency.

3. Wide temperature tolerance and environmental compliance advantages

The wide operating temperature range of -40 ° C to + 105 ° C makes it suitable for multi-scene needs from the cold outdoor in the north to industrial high temperature equipment. There is no need to customize the connector model according to the environment, which reduces the inventory cost of the enterprise. In addition, the product fully complies with RoHS environmental protection standards and has passed UL certification to meet the environmental protection and safety regulations of the global mainstream market, providing convenience for the export of enterprise products and reducing compliance risks.

4. The flexible advantages of diverse types and automated adaptation

The series offers two connection types: wire-to-wire (Wire-to-Wire) and wire-to-board (Wire-to-Board). It has been developed and designed to support up to 16 circuits, which can be adapted to the connection needs of different devices. Diversified product types and assembly solutions enable the series to quickly respond to the customized needs of different industries such as home appliances, automobiles, and industries, and enhance products.

The JVT2070 waterproof connector system takes "IPX7 waterproof, compact structure, stable contact, wide-area adaptation" as its core characteristics. Through innovative designs such as double seal and double spring contact, it has realized reliable applications in many fields such as automotive electronics, household appliances, industrial equipment, two-wheel new energy travel and power tools. Its advantages of "taking into account both performance stability and cost optimization, standardization and customization" make it the preferred solution for medium and low power waterproof connection scenarios. For enterprises, choosing this series of connectors can not only improve the reliability and safety of products, but also reduce production and compliance costs, providing support for product competitiveness.