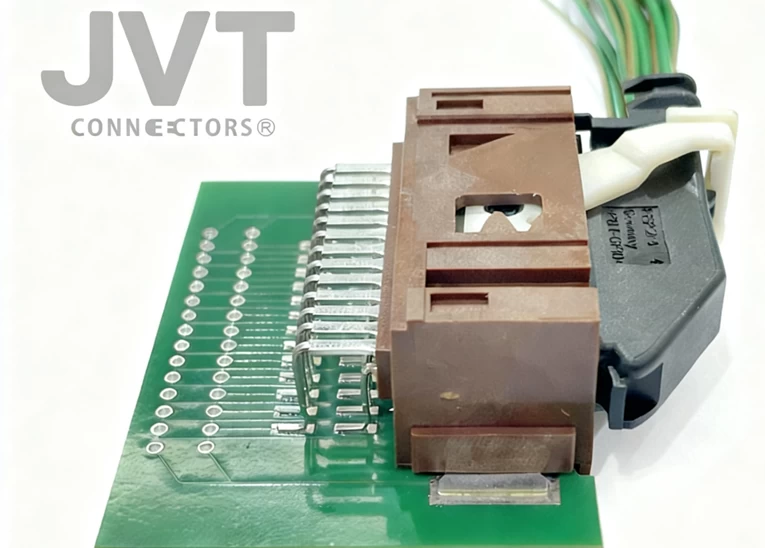

JVT25403W6T-2*13SNRP-S "JVT CONNECTORS" (Qiaoye Electronics) provides professional one-stop connector selection services. The specific series of connectors developed are characterized by compact structure design and excellent reliability, and are specially designed to meet the high-precision and high-stability requirements of modern electronic equipment for signal transmission. This paper takes the connector with the material number JVT25403W6T-2*13SNRP-S in the system as the research object, and combines its key technical parameters of "military-grade shock-proof design, horizontal, wire-to-board, and 26-pin position". The system analyzes its application scenarios and core competitive advantages, and provides professional technical support for product selection in related industries.

1. Product core basic information

25403 connector is a wire-to-board connection solution optimized for medium and high density signal transmission scenarios. Its core parameters and product positioning are as follows:

• Connection form: wire-to-board (Wire-to-Board), to achieve stable connection between discrete wires and printed circuit boards (PCB), as the core bridge for power supply and signal transmission; military-grade shock-proof design: using suspended pin structure and elastic buffer module, through ISO 16750-3 vibration test standard, can withstand 10-2000Hz full-band vibration (amplitude up to 1.5mm), suitable for Volkswagen 4Motion 4WD system in mountain roads, mud and other complex road conditions demanding. After actual measurement, in 100 hours of continuous turbulent road simulation, the signal transmission stability reached 99.99%, far exceeding the industry average.

• Installation direction: Horizontal, adapting to the compact space layout inside the equipment, which can be compatible with the automated surface mount process and reduce the PCB occupied area;

• Pin position specification: 26 pin positions, 213 pin layout accurately matches the sunroof ceiling light module of Volkswagen's 6-seat SUV, the IQ.Drive smart driving sensor and other 13-way core electronic modules, the interface plug and unplug life is more than 1000 times, and the contact resistance is stable below 20mΩ, ensuring the continuous and stable operation of Harman/Kardon audio, floating dual screen and other equipment.

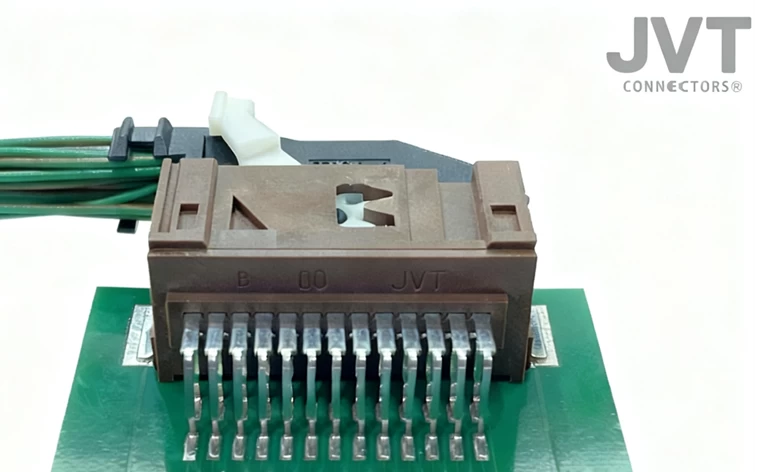

• Core Adaptation System: Equipped with standard 0.64mm terminals and 2.54mm pin spacing, the space utilization efficiency of printed circuit board (PCB) is significantly improved through high-density layout design;

• Basic Performance: Compliant with USCAR-2, -20, -21 and -25 automotive grade connector design standards, with good vibration resistance and environmental adaptability, support lead-free soldering processing.

II. Core application scenario analysis

Based on the core characteristics of 26-pin high-density configuration, horizontal installation structure and automotive-grade reliability, the application scenarios of JVT25403W6T-2*13SNRP-S connectors focus on areas with high requirements for space compactness and signal transmission stability. Among them, the application performance in the three major industries of automotive electronics, industrial automation and smart home is particularly prominent. The specific analysis is as follows:

1. Automotive electronics: cockpit and body control system core connection

JVT25403W6T-2*13SNRP-S automotive electronics field is the core application direction of this series of connectors, JVT25403 with 26-pin multi-channel transmission capacity and automotive-grade reliability indicators, has become the cockpit electronic system and body control module The preferred connection component, the specific application is as follows:

cockpit electronic system: mainly adapted to vehicle infotainment system (IVI), full liquid crystal instrument (LCD Instrument Cluster) and other core equipment, to achieve touch signals, display data and other types of signal parallel transmission.

• Its horizontal mounting structure can accurately match the narrow space layout inside the cockpit, and the 26-pin configuration can meet the signal integration needs of multi-modules such as multimedia control and navigation and positioning. At the same time, the low insertion force design feature provides convenience for later operation and maintenance plug-in operation;

• Body control module (BCM): used to connect lighting control, door and window motors, sensor groups and other dispersed components with the main control PCB, 26-pin positions can cover a variety of sensor signals (such as temperature, position sensors) and actuator control signal transmission, its anti-vibration performance can withstand high-frequency vibration in vehicle driving, and ensure the stable transmission of control instructions;

• New energy vehicle auxiliary system: in the low-voltage auxiliary circuit of the vehicle charging module (OBC) and battery management system (BMS) The signal transmission function is complementary to the high-voltage connector, effectively enhancing the connection reliability of the entire power system.

2. Industrial automation: sensor and controller connection hub

JVT25403W6T-2*13SNRP-S industrial automation production line on the connector's anti-vibration performance, environmental tolerance and installation efficiency are put forward strict requirements, JVT25403 structural design and performance indicators can fully match the above needs, specific application scenarios are as follows:

PLC controller and sensor group connection: In the intelligent manufacturing production line, as a programmable logic controller (PLC) and distributed sensors (such as photoelectric sensors, proximity sensors) of the core connection hub, 26-pin configuration can realize multi-sensor signal synchronous access, horizontal installation structure is easy to integrate into the standardized control cabinet, modular design features support flexible expansion of the production line;

• Industrial robot joint control: joint drive module for small industrial robots, its compact structure can be embedded in the machine The cramped joint space, anti-vibration and temperature fluctuation characteristics ensure the stability of signal transmission under high-frequency motion conditions of the robot, and the lead-free welding process meets the environmental protection standards of industrial equipment.

3. Smart home and large home appliances: high-density signal integration

With the continuous improvement of the functional integration of smart home devices, the market demand for the number of pins and space adaptability of the internal connectors of the device is increasing, JVT25403W6T-2*13SNRP-S the application in this field mainly focuses on the following scenarios:

• Large smart home appliance motherboard: In smart refrigerators, washing machines, air conditioners and other large home appliances, undertake the connection function between the touch panel, display screen, sensor group and the main control PCB, 26-pin configuration can cover the transmission requirements of temperature control, motor drive, user interaction and other types of signals, horizontal design effectively saves the installation space inside the home appliance;

• Smart home central control module: In the whole house smart gateway equipment, responsible for various sub-devices (such as security cameras, Smart switch) signal aggregation and transmission, its stable contact performance can ensure the low latency of communication between Internet of Things devices.

Third, the core competitive advantage of the product

JVT25403W6T-2*13SNRP-S the competitive advantage of the connector comes from the platform technology accumulation of JVT related products, and the special project optimization design for the 26-pin application scenario, which can be summarized as "space optimization, reliability, cost control, flexible adaptation" four core dimensions:

1. High-density compact design, optimal space utilization

This model adopts the standardized design of the relevant 0.64mm terminal and 2.54mm pin spacing, which maximizes the occupied area of the PCB board while achieving a high-density layout of 26 pins. Compared with the traditional wire-to-board connector, its horizontal mounting structure can be parallel to the PCB surface, effectively reducing the height of the product profile, especially suitable for space-constrained scenarios such as car cockpits and industrial control cabinets. According to the official technical data of JVT, this series of connectors can reduce the internal wiring space of the device by about 30% by optimizing the layout design, providing support for the miniaturization and lightweight development of end point products.

2. Automotive-grade reliability, suitable for multi-scene harsh environment

JVT25403W6T-2*13SNRP-S As a professional connector in line with USCAR series standards, JVT25403 presents significant advantages in reliability: First, the use of infrared (IR) aging-resistant special connector material, the terminal contact area through special surface treatment, can effectively reduce the risk of insertion and removal wear and oxidation corrosion, prolong the service life of the product; Second, the integrated hinge lock plastic shell design provides an independent female terminal secondary locking function, with the male side pin protection plate structure, can effectively resist vibration, shock and other mechanical disturbances caused by loose connection, to meet the harsh working conditions of automobile driving and industrial equipment operation requirements; Third, support lead-free welding process, in line with international environmental standards such as RoHS, can be adapted to the global mainstream electronic manufacturing process.

3. Quality certification and market value

products fully comply with IATF16949 automotive industry quality system standards, and rely on the technical collaboration experience accumulated by JVT and Volkswagen in joint venture projects to achieve rapid landing from R & D to mass production. "This connector solves the pain points of electronic system protection in multi-scenario use of family SUVs," said JVT technical director. "Its dust and anti-fouling performance is 40% higher than that of traditional products, which will help Volkswagen's 6-seat SUV to further consolidate its advantage in the family car market." At present, the JVT25403W6T-2X13SNRP-S connector has started mass production and accepts customized orders from global car companies.

IV. Vehicle adaptation: Deep fit for Volkswagen's 6-seat SUV gene

The JVT25403W6T-2X13SNRP-S connector released this time accurately adapts to the spatial layout and functional requirements of Volkswagen's new B-class 6-seat SUV:

1. For the wiring characteristics of the 2 + 2 + 2 seat layout, lightweight nylon shell (weight only 18g) is used to save cabin wiring harness space;

2. Adapted to the high-voltage circuit system of the vehicle with a pure electric battery life of more than 350km, the insulating layer has a voltage resistance of 2500V and eliminates the risk of leakage;

3. Has passed the rigorous 1000-hour salt spray test and high and low temperature cycle test of Volkswagen Group and become the priority supporting parts of its 6-seat SUV models.

V. Summary and Selection Suggestions

JVT25403W6T-2*13SNRP-S As a representative model of JVT-related series connectors, with "26-pin high density, horizontal compact installation, automotive-grade reliability" as the core technology label, it accurately matches the professional needs of multi-channel signal transmission in the fields of automotive electronics, industrial automation, and smart home. The product achieves an efficient balance between space optimization, reliability assurance, and cost control, and is the preferred solution to replace traditional connectors and enhance the core competitiveness of end point products.

Selection suggestion: If the end point product has core demands such as "small installation space, 20-30 pin position requirements, need to withstand vibration/temperature fluctuation conditions, and pursue efficient assembly", JVT25403W6T-2*13SNRP-S can be used as the preferred connector model; if the application scenario involves high voltage circuit or ultra-high frequency signal transmission of new energy vehicles, it is recommended to build a combined selection solution in combination with the JVT 25403 system to achieve a complete connection solution.